Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Refractory Brick Technology ->

1.Construction procedure of dynamic furnace

The dynamic kiln masonry can only be carried out after the single no-load test and acceptance.

Laying the basic procedure is: the choice of the starting point, from the hot end to the cold end or from low-end to high-end brick masonry in turn - operating point clear line - choose, according to different material of refractory brick, hot and cold period need choose qualified brick - if there are anchoring nails or brick plate, namely to anchor nails or Joe brick plate welding - if there are heat insulation layer (such as calcium silicon plate, etc.), need to undertake the installation of the insulation layer - > mortar first modulation and use, should match the refractory brick and mortar mud brick - expansion slot reserved and filling.

2.Construction procedure of static furnace

Starting point selection → marking → brick selection → anchoring nail and supporting brick plate welding according to the requirements of the drawings → if there is heat insulation layer, install the heat insulation layer first → mortar mixing and use, mortar mortar material should match firebrick → masonry arch, lock brick, remove arch tire → reservation and filling of expansion joint.

Relevant Product Display

Ceramic fibre blanket

Ceramic fibre blanket

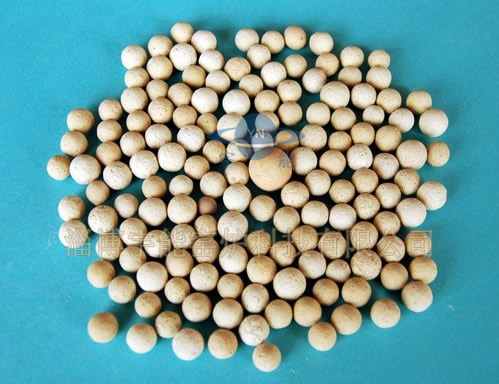

Regenerative ball

Regenerative ball

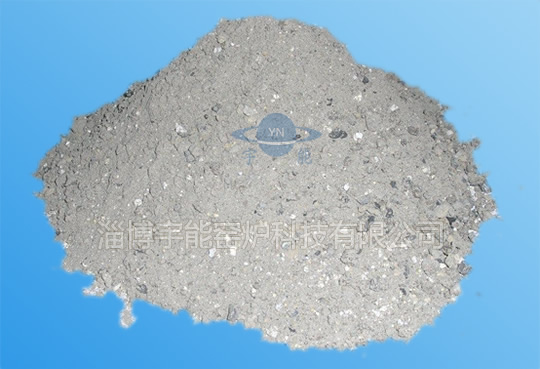

High aluminum and high strength castable G-16

High aluminum and high strength castable G-16

Lightweight insulating castable YL-8N

Lightweight insulating castable YL-8N

Relevant information

Hotline