Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

One-stop solution for building a large-scale power plant circulating fluidized bed boiler

Ultra-durable anti-erosion technology + fine selection of materials + long-term research and development test

Let us solve the problem

Home -> Product -> Castable Series -> Metallurgical industry -> The ironmaking system -> The blast furnace body ->

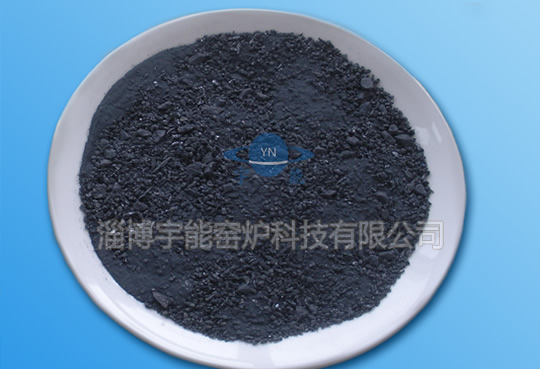

Series of iron ditch castable for 2000 cubic blast furnace

Hotline:+8613864463333

Product specification [product name] : series of iron ditch castable for large blast furnace [product model] : mt-mg, mt-tg, mt-zg, mt-my Recommended site: blast furnace body Product information [performance characteristics] : mt-mg, mt-tg, mt-zg, mt-my are low-cement refractory castable used in the iron channel of large blast furnace. The main materials are brown corundum, high-quality bauxite, high-purity silicon carbide, etc., and cement is used as the binding agent. In this product, high-performance water-reducing agent and explosion-proof agent are added to improve the construction performance and service performance of the product.Material properties: 1) strong resistance to corrosion and erosion of molten iron and slag; 2) good thermal shock resistance and small change of reburning volume; 3) strong antioxidant capacity; 4) good workability and liquidity of construction stirring materials; 5) no harmful gas, no slag iron, long service life. Construction and preservation method: Vibration pouring construction. Plastic coated woven bag packaging, packaging specifications of 1000kg/ bag or 500kg/ bag; Store in a dry, ventilated, moisture-proof and sun-resistant warehouse. Generally, the maximum storage life is 6 months. [application site] : mt-mg is recommended to be used in the main iron groove of large blast furnaces, and can also be used to repair the impact zone of the main groove. Mt-tg, mt-zg and mt-my are recommended to be used in the permanent lining site of large blast furnaces. Performance indicators

Model No. MT-MG MT-ZG MT-TG MT-MY Chemical conposition(%) AL203≧ 70 55 70 70 SiO2+C≧ 14 15 10 10 Volume density (g/cm3) 110℃*24h 2.9 1450℃*3h 2.9 2.6 2.7 2.8 Bending strength(MPa)≧ 110℃*24h 8 6 3 7 1450℃*3h 10 7 7 8 Pressive strength(MPa)≧ 110℃*24h 40 35 35 35 1450℃*3h 45 45 45 50 line changes(%) 1450℃*3h ±0.3 ±0.3 ±0.3 ±0.3 form of construction The main iron and purchasing The slag iron ditch The iron ditch Main ditch permanent lining

Zibo Yuneng Kiln Technology Co.,Ltd. is the professional Series of iron ditch castable for 2000 cubic blast furnace manufacturer in Shandong。Our company Series of iron ditch castable for 2000 cubic blast furnace sincerely obtains the prestige,rewards our customers with the preferential price of Series of iron ditch castable for 2000 cubic blast furnace and warm service。Our main products:refractory castable,high strength castable,alumina silicate fiber module,alumina silicate felt,alumina silicate fiber blanket,alumina silicate cotton,etc。The products sell well in dozens of metallurgical,chemical and electric power enterprises all over the country and are well received by users。The company's unique production process,quality management and testing equipment to ensure product quality and stability,has a high-quality staff and professional and technical personnel,according to the different requirements of users,the development and design of a variety of new refractory materials。To know the latest Series of iron ditch castable for 2000 cubic blast furnace price can be posted on our website https://www.zbyuneng.cn,we will contact you within 24 hours,Tel: 13864463333 Manager Sun。

Relevant Product Display

Aluminosilicate fibre castable ceramic fibre castable

Aluminosilicate fibre castable ceramic fibre castable

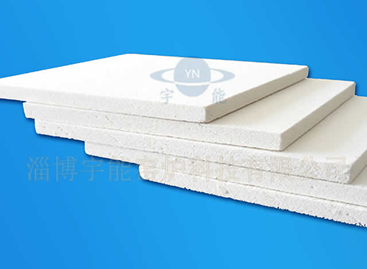

Standard aluminum silicate plate

Standard aluminum silicate plate

LT-5C Series of heat-resistant and wear-resistant single layer lining ..

LT-5C Series of heat-resistant and wear-resistant single layer lining ..

Aluminosilicate fibre castable ceramic fibre castable

Aluminosilicate fibre castable ceramic fibre castable

Relevant information

Hotline