Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Industry News ->

RCO exhaust gas treatment equipment structural features:

1. Convenient operation: automatic control when the equipment is working.

2, low energy consumption: the equipment starts to heat up to about 20 minutes to start the combustion temperature, when the organic exhaust gas concentration is higher, the energy consumption is only the fan power.

3, safe and reliable: the equipment is equipped with fire retardant system, explosion-proof pressure relief system, over-temperature alarm system and advanced automatic control system.

4, low resistance, high purification efficiency: the use of today's advanced precious metal palladium, platinum impregnated honeycomb ceramic carrier catalyst, large specific surface area.

5. Residual heat can be reused: residual heat can be returned to the drying tunnel to reduce the power consumption in the original drying tunnel; other sources of heat can also be used.

6. Small footprint: only 80% of similar products in the same industry, and there is no special requirement for equipment foundation.

7. Long service life: The catalyst is generally replaced in 4 years, and the carrier can be regenerated.

RCO equipment application range:

1. It can be used for the purification treatment of organic solvents (mixed organic waste gas such as benzene, alcohol, ketone, aldehyde, ester, phenol, ether, alkane, etc.).

2, suitable for wire, cable, enameled wire, machinery, electrical, chemical, instrumentation, automotive, bicycle, motorcycle, engine, tape, plastic, household appliances and other industries of organic waste gas purification.

3, can be used in a variety of drying tunnels, printing iron cans, surface spraying. Printing ink, electromechanical insulation treatment, leather shoes and other drying lines to purify the organic waste gas generated by each process.

Relevant Product Display

Outside furnace refining system castable

Outside furnace refining system castable

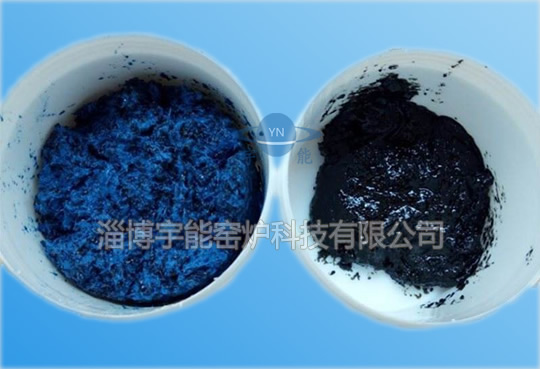

High wear resistance toughness ceramic coating TD-YMT

High wear resistance toughness ceramic coating TD-YMT

Vacuum forming abnormal products

Vacuum forming abnormal products

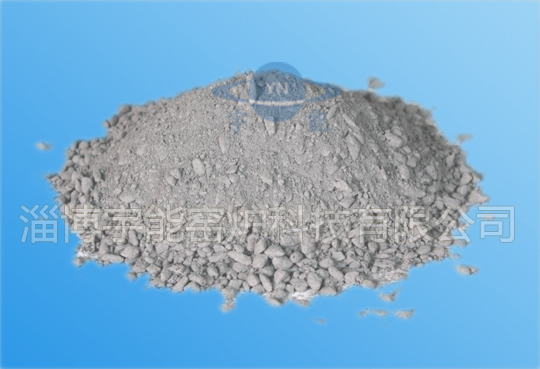

High strength refractory castable DC-17

High strength refractory castable DC-17

Relevant information

Hotline