Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

Castables are the most widely used amorphous refractory materials in the refractory industry. There are many different products on the market. How do we judge the quality? Here is a brief introduction to the problems that should be paid attention to during the selection of castables: users should use unshaped refractory materials, such as castables, plastics, etc., first check the expiration date. After opening the product packaging, be sure to carefully check the date of manufacture on the packaging. If the product exceeds the specified period, the performance of the castable will decrease.

The particle size, strength and composition of the castable have a very important impact on the quality of the masonry. Check the particle size shape, generally by visual means. For example, the particle size of the knotted induction furnace is preferably rhomboid and has a sharp angle. Check the particle size strength by tapping with a wooden hammer and judging the crushing condition. Check the size and composition of the particle size and use the screening method. The sieving method is carried out in the laboratory and it can measure the composition of various particle sizes.

After determining the raw materials used, the castables are subjected to a series of production processes to produce suitable castables, which are then cured according to appropriate methods, and finally the structures are properly baked and put into use. Because the construction process of castables is also very important, pay attention to the amount of water added during the construction of castables. The castable should contain a certain amount of water, and the specific amount of water should be analyzed according to the actual situation. For example, calcium aluminate cement can be mixed with a binder to prepare an aqueous solution, which is preferable for those which require hydrolysis in advance.

The hardening speed of the cement in the castable is closely related to the amount of water added. The most appropriate water-cement ratio should be selected at the peak of the water-cement ratio curve. Not only related to the type of cement, but also related to the shape properties of the particles. During construction, in order to ensure the strength of the castable, the water-cement ratio is generally controlled at about 0.4 to 0.6, and the moisture in the mixture is about 5% to 6%.

Of course, the choice of castables is more important, depending on the specific use of the user. Rongsheng kiln specializes in producing all kinds of high temperature, wear-resistant castables, plastics, refractory bricks, etc., with favorable price, independent production, and construction services, the quality can be used with confidence. Welcome to visit our company. Our company relies on nearly 20 years of technical experience to recommend suitable products according to your needs!

Relevant Product Display

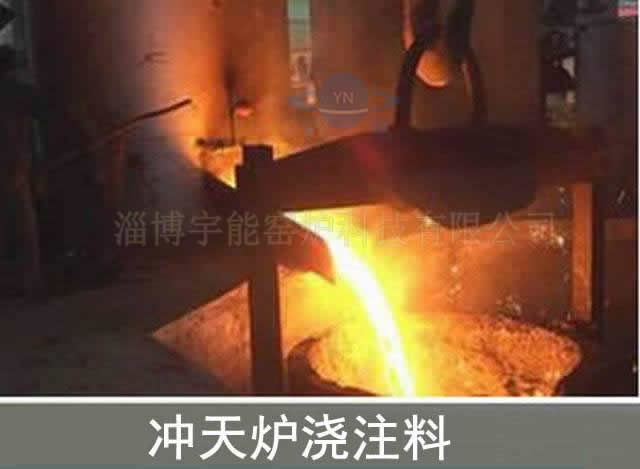

Castable for cupola

Castable for cupola

Silicon carbide

Silicon carbide

High resistance ramming material GT-2AS

High resistance ramming material GT-2AS

Aluminum silicate fiber cotton, shake silk cotton

Aluminum silicate fiber cotton, shake silk cotton

Relevant information

Hotline