Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

| Hearth top |

Corundum castable YG-GJS-13 |

Alumina aggregate40 Alumina powder5 Corundum40 additive15 | Refractories>1790℃;Bulk density>2.8 g/cm3; Normal temperature compressive strength>90 Mpa; Flexural strength>9 Mpa; Reburning line change rate0.2%; Thermal shock stability>40次; Maximum working temperature1350℃Wear resistance<8cc | 4 year above | It can be plastic with corundum. This part needs to have three physical properties: fire resistance, wear resistance and thermal shock stability. Because of the inconvenient construction of the parts, it is made of wear-resistant plastic. This material is composed of three reasons; (1) the alumina aggregate plays a role in fire resistance; (2) Al2O3 powder, which plays a role of thermal shock stabilization; (3) Corundum material, which plays a role in wear resistance. |

| Furnace exit |

corundum plastic refractory YG-GJS-13 |

Alumina aggregate40 Alumina powder5 corundum 40 Additive15 | Refractories>1790℃;Bulk density>2.8 g/cm3; Normal temperature compressive >90Mpa; Flexural strength>9Mpa; Reburning line rate0.2%; Thermal shock stability>40次; Max working teemperature1350℃Were resistance<8cc | 4 years above | Used in corundum plastic. With the furnace outlet, wear-resistant plastic material. |

Relevant Product Display

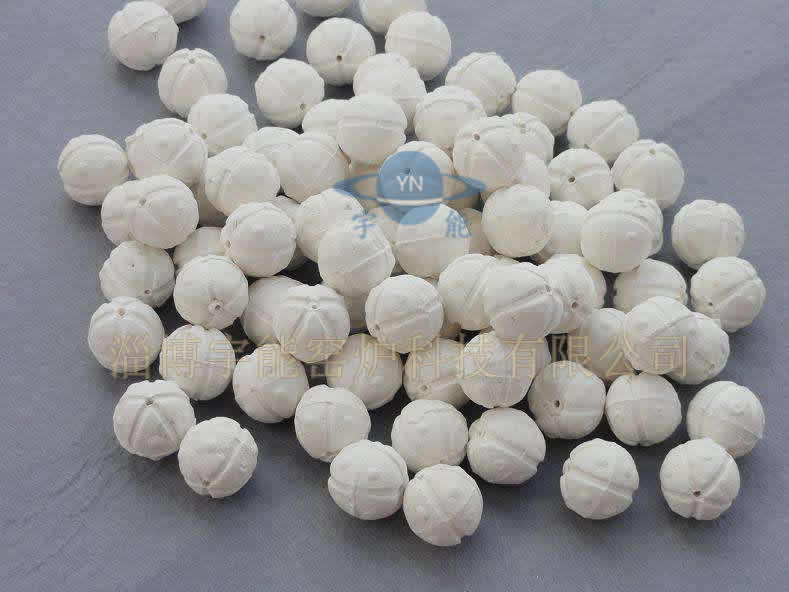

High aluminum wear-resisting ball

High aluminum wear-resisting ball

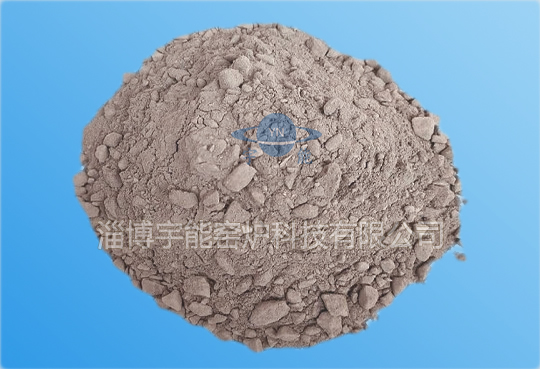

A new type of uniform wear-resistant refractory castable SM-20

A new type of uniform wear-resistant refractory castable SM-20

High aluminum and high strength castable G-16

High aluminum and high strength castable G-16

LT-5C Series of heat-resistant and wear-resistant single layer lining ..

LT-5C Series of heat-resistant and wear-resistant single layer lining ..

Relevant information

Hotline