Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

Refractory castable is an unshaped refractory which is constructed by casting method and can be hardened without heating.It is composed of refractory aggregate, powder, binder, admixture, water or other liquid materials.Generally in the use of the site by casting, vibration or tamping method of casting molding, can also be made into prefabricated parts for use.

Castable as a new type of refractory material, its main characteristic is to have high liquidity, is a kind of monolithic refractories, compared with other monolithic refractories, binder and moisture content is higher, good liquidity, not stereotypes refractories has a wide application range, according to the conditions of use of the materials and the binder used to make choices.Can be directly poured into the liner for use, and can be made into the method of pouring or vibration precast block use.

Refractory castable both parts use the quality of the material, and its design and construction are more successful, refractory castable is mostly used in the preheater system has not changed, the use of other parts of the cycle are mostly ideal through the construction of the first production line, the zibo yu can kiln technology company has developed a technology level high furnace building construction team, contributing to the construction of many domestic factories.

Companies in the design of the refractory castable have had some experience in the construction and use, and also has a lot to learn from the lessons, and the use of refractory castable for cement kiln refractory castable used in the meter, the highest frequency of thermal shock because of its position in kiln, each stop kiln, born the brunt of the cold and hot shock is kiln mouth castable and every time after a long time to stop kiln, from ignition to feeding, although the wicket castable by flame thermal radiation gradually rise be like, but because of the flame is in the direction of preheater, so the temperature of the castable at that point has been temperature is much lower than after feeding, and uneven, so after the clinker from reaching after feeding,Directly in contact with the pouring material, the temperature rise within a short period of time is conceivable, so the possibility of pouring material burst or internal crack is very large.

Because the kiln skin is not very stable, some kilns rarely have kiln skin, so from the firing of a certain degree of cooling hardening of the clinker particles from here fell into the cooling machine, thus causing more serious wear of castable.In addition, alkali, salt, coal ash, smoke and other internal low-melting phase erosion, castable by multiple effects, naturally easy to damage.Winter time is relatively long, because according to the needs of the market.Kiln maintenance is often arranged in winter, which increases the difficulty of castable construction, quality is difficult to ensure.

However, construction shall be carried out in strict accordance with the requirements of regulations, and water addition shall be strictly controlled. On the premise of ensuring compaction, water addition shall be reduced as far as possible. Forced mixer and electric vibrating rod shall be used for stirring.Castable material and formwork firebrick contact part to take waterproof measures.

In the process of pouring material construction and after the completion of the construction, the furnace is born at the bottom and both sides of the kiln mouth, and the kiln head cover is covered on the pouring material surface and baked with high-power lamp (this measure is only used in winter).

Through technical communication with foreign experts, we analyzed inside out a way to help feed water discharge, kiln hood wall castable construction should be set aside in the vent, to prevent the ignition temperature of castable heated too fast, the internal temperature gas does not discharge in time, causing uneven floor heats of inside and outside, make castable crack or even fall off, specific drilling requirements: use air flushing drill holes, 300 mmx300mm spacing, and & Oslash;The embedding depth of 5mm wood strip is half of the pouring material.

After the overhaul of the heater in the kiln, firewood is burned at the discharge area of the grate in the high-temperature area until the temperature of the kiln reaches a higher level.This measure is taken in combination with the process conditions of the factory.General castable requirements of some heating time, and the factory is reluctant to spend so long time special baking castable, all hope to cast as soon as possible, so as to give the product, a benefit.During a considerable period of time after ignition and temperature rise, although the end of the kiln has reached a higher temperature, the temperature at the kiln mouth is still low. The above measures ensure the uniform temperature rise of the kiln mouth and avoid the damage of refractory castable caused by sharp temperature rise during feeding.

Relevant Product Display

Ceramic fibre textile

Ceramic fibre textile

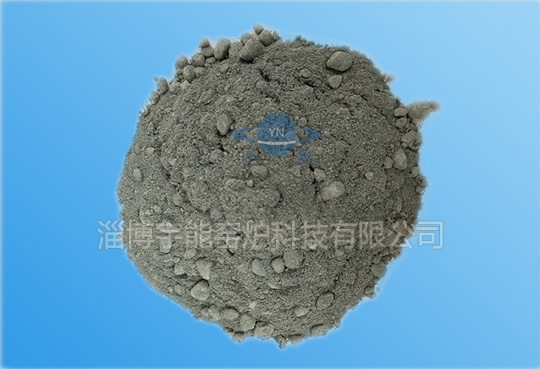

No cement castable low cement castable

No cement castable low cement castable

High wear and erosion resistant castable G-17M

High wear and erosion resistant castable G-17M

Silicon carbide

Silicon carbide

Relevant information

Hotline