Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Zibo Yunneng Kiln Technology Co. Ltd. Zibo Yunneng Kiln Technology Co. Ltd.

Free delivery samples

high quality assurance

Engineer's door-to-door guidance

lifelong technical support

Contact us+86159669653330086-533-5331887

Home -> News -> News -> Castable Technology ->

The construction of refractory castable consists of three steps: mixing, pouring and maintenance. 1, mixing: must use forced mixer or mortar mixer mix, can not use artificial mix.Equipment and tools: forced or mortar mixer, bucket, scale, vibration bar, tool shovel, barrow, etc.Mixing: first add big bag material to the mixer, then add small bag material, dry mix 1-2 minutes, before discharging for pouring.Water content determination method: in order to determine whether the water content of the stirring material is appropriate, a simple "hand kneading" method can be used for testing: if the pellets are deformed and flow out of the hand seam, it means too much water content; if the pellets are cracked and scattered, it means water content Quantity is too little.Mixing water consumption: take the water consumption given in the instructions for this batch of products as the standard, strictly control the water consumption and accurately measure it.Notes: (1) the construction process of tools such as stirrer, bucket, tool shovel, etc. need to be cleaned up in advance, not mixed with lime, gravel, Portland cement and other debris. (2) mixing water must be clean tap water.In the case of vibration out of pulp, as little water as possible, has achieved better construction results. (3) each mixing amount is not too much, should be based on the type of mixer model, otherwise it will cause the mixer stuck, stop.Pour the rest of the solidified block material can not add water and mix again for use. (4) the construction site temperature must be between 5-30℃, such as the construction site temperature below 5℃, must take appropriate warming protection measures before construction: such as the site temperature above 30℃, must use the corresponding cooling protection measures before construction: otherwise, will cause product construction difficulties or performance decline.

2. Pouring construction: check: before pouring material construction, check whether the anchoring parts are solidly welded and adopt heat-resistant nails for parts above 500℃.The surface of the anchorage parts shall be painted with 0.5-1mm thick paint or wrapped with plastic tape to buffer the expansion force after heating and remove the sundries in the mold.Pouring time control: the newly mixed castable should be poured quickly, and generally finished within 20 minutes.Pouring: pour the mixed castable material into the mold, and insert the vibrator in time to vibrate evenly. Move the vibrator when the grouting on the surface of the castable is in a flowing state, with a moving speed of 1-2 m/min.Remove the vibrator slowly.After pouring, the field temperature should be controlled: the field temperature must be kept above 5℃ (5-30℃) and below 5℃ after pouring, otherwise the temperature will be delayed and the product performance will be reduced. Notes: (1) after the vibration of the castable surface should be kept natural, should not be wiped with tools, more do not allow on the surface of cement powder wipe. (2) the vibrator should have a backup, so as to avoid failure of the vibrator, the backup rod can be used in time. (3) after the completion of the construction, the construction body within 24 hours, especially before the hardening of the pouring material, it is strictly prohibited to move, shake or pound, otherwise, the pouring will produce cracks or even complete damage. (4) pouring material should be continuous construction, because of various reasons can not be continuous construction, can stay construction seam, and stay at the expansion seam, otherwise the construction seam made of hemp surface, that is, on the pouring material delimit 10mm deep, wide 20mm about the cross groove, spacing 100mm or so.

3. Maintenance: tools: polyethylene plastic film, straw bag, etc.Requirements and control of ambient temperature: it is appropriate to maintain the pouring body between 15-35℃. If the temperature is beyond this temperature range, corresponding heating or cooling measures should be taken; otherwise, the product performance will decline.Maintenance: immediately cover the construction surface with polyethylene plastic film after hardening of castable, and then cover with wet straw bag to prevent water evaporation and promote cement activation.After hardening, it is forbidden to knock or shake within a day. According to the hardening situation, mold can be removed after hardening for 24-30 hours.After removal of the mold, according to the need to maintain 2 days, maintenance continue to cover polyethylene plastic film and wet straw bag.After oxidation for 3 days, remove polyethylene plastic film and wet straw bag.Allow the pouring body to dry naturally in the air for 1 day before baking. |

Relevant Product Display

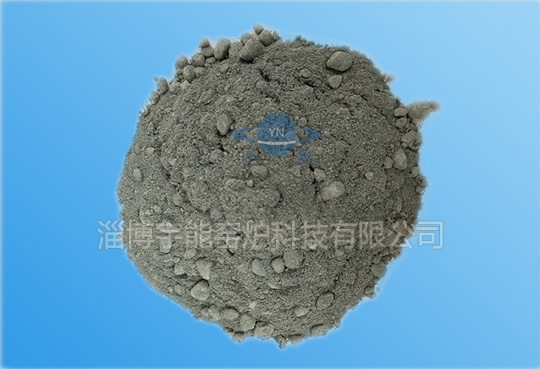

High wear and erosion resistant castable G-17M

High wear and erosion resistant castable G-17M

Corundum wear-resistant plastic _ boiler repair compound

Corundum wear-resistant plastic _ boiler repair compound

High alumina castable

High alumina castable

DL Series of light insulation refractory castable

DL Series of light insulation refractory castable

Relevant information

Hotline